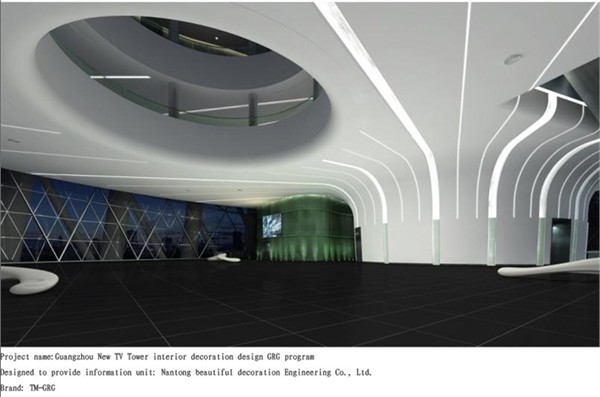

Chinese name:Pre-cast Glass fiber-reinforced plaster moldings

English name: Glass Fiber Renforee Gypsum

Referred to as:GRG

Brand: TM-GRG

Features: It is mainly to thin-walled, light weight, high strength and incombustibility and indoor humidity regulated environment, to achieve their comfortable living environment. Its high-strength, high hardness and good flexibility, and was eventually made to meet any shape, specifications and quality results. 120 ℃ in high temperature storage for 72 hours without distortion.

Such material can be made from a variety of flat panels, features a variety of products and a variety of art forms, is the international construction materials sector, the most popular product replacement. Under normal circumstances, an architect who often recommended in the industrial and construction applications for high impact resistance and increase the stability of the ceiling of the main In addition, TM-GRG material and good waterproof properties of the acoustic performance is especially suited for frequent Clean and wash the voice transmission, such as schools, hospitals, shopping malls, theaters, and other places.

TM-GRG project to use the material advantages and features:

1. High-strength, impact resistance: experiments show that, TM-GRG products fracture load greater than 1200N, exceeding the national standard JC/T799-1988 (1996) decorative gypsum board fracture 118N load 10 times. Products never deformed, a small expansion coefficient.

2. Flexibility: TM-GRG products are of high hardness but also a very good flexibility, it can be made from a variety of sizes, shapes, forms and designs, easy-to-use, but also can be used in decorative ceiling in the complex.

3. High-density and light: TM-GRG flat products for the Department of the standard thickness of 3.0 to 6.0mm (special request can be thickening) per square meter weight of only 6.0to 9.0kg, can reduce the weight and construction of the main components load.

4. Fire Performance: TM-GRG materials belonging to the A-class fire protection materials, in addition to its fire-retardant, is also the release of the equivalent weight of its own 10-15 percent of the water, fire, can be greatly reduced surface temperature.

5. Moisture resistant: The test results prove the product was only 0.3 percent of the water absorption, so TM-GRG products can be used to damp environment.

6. Environmental Protection: TM-GRG materials without any odor, radionuclides GB6566-2001 in line with the limits stipulated in the Class A decorative materials. Recycling can be, is a green material.

7. Acoustic effective: Testing shows that: 4mm thick TM-GRG materials, through the loss of 500Hz 23db, 100Hz 27db; air-dry weight in line with the 1.88 acoustic reflex professional requirements. After a good design, may constitute a good sound absorption structure to noise, sound-absorbing.

8. Short production cycle: TM-GRG products Tuomo time only 30 minutes, drying time takes only 4 hours. Thus greatly shortening the construction period.

9. Construction easy: TM-GRG according to the designer in the design, any shape can produce large, split. On-site processing performance, and the installation of rapid, flexible and can be carried out large areas of dense seamlessly together to form a complete shape. Especially the hole, curved, fine, and so on the corner, to ensure that no error. By the long-term test.

所有评论